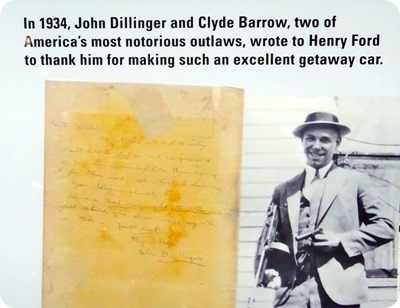

Monday, July 20 – Our last day in Dearborn, Michigan, was spent at the Ford Rouge Factory – part of the Henry Ford. The Rouge initially produced submarine chasers, or Eagle Boats, then tractors. The Model A was the first car produced there, beginning in 1927. At its peak in the 1930s, more than 100,000 people worked at the Rouge. To accommodate them required a multi-station fire department, a modern police force, a fully staffed hospital and a maintenance crew 5,000 strong. One new car rolled off the line every 49 seconds. Each day, workers smelted more than 1,500 tons of iron and made 500 tons of glass, and every month 3,500 mop heads had to be replaced to keep the complex clean.

This is the factory where the new aluminum body Ford F150 is assembled.

After taking a short bus ride from the Henry Ford Museum to the Rouge Factory, we began the tour with a historical film in the Legacy Theater. An interesting historical fact we learned from the film is Henry Ford tried auto production three times before he was successful. Twice he lost everything and had to rethink his dream.

After the film, we moved to the Manufacturing Innovation Theater where everything from robots to laser beams are use to light up your senses illustrating the production of the new F-150 from concept to highway. It really is a pretty amazing production. No photos permitted in this theater.

We exited the second theater into the Legacy Gallery. Here we walked past the historic vehicles made at the Rouge factory. Included are the Ford Model T, the Mustang, the Thunderbird, and of course the F-150. Quite a history for this factory that in its heyday employed nearly 100,000 workers. They currently have 2000 hourly workers that work two 12-hour shifts.

The last, and perhaps the most interesting aspect is the walking tour. Absolutely no photos permitted in this area. We were free to roam at our own pace along an elevated walkway over the entire production floor. In order to mass produce the new aluminum body Ford 150, the entire factory was gutted and rebuilt in three months. During that time, the workers were being trained to learn how to use the new technology.

During our walking tour, we saw the cabs being assembled and then attached to the box. Also, the glass being set in the cab and all the doors, the interiors put in place and the bumpers and lights. Last was the final F-150 rolling off the assembly line and being tested. They test every truck before it is called complete. I think we saw everything but the painting department and the placing of the body on the chassis. Those departments were not able to be seen from the viewing platform. The installation of the windshield and back window was the only place we saw only robots doing the work. Men and women do all the assembling.

It was a wonderful tour and one we are glad we took. We were not as exhausted after this portion of the Henry Ford. Today we only walked 6,027 steps and 2.92 miles on the tour. Guess you could partner this tour with one of the other shorter excursions at the Henry Ford if you selected carefully.

Thanks for stopping by. Hope to see y’all back real soon. Have a great day!